The digital revolution, with its introduction of 3D technologies, has profoundly transformed the dental laboratory. The term “3D technologies” refers to all those tools — hardware and software — that are an integral part of the CAD-CAM (Computer Aided Design – Computer Aided Manufacturing) workflow (1–3).

Today, 3D printers, CAD/CAM software and benchtop scanners are everyday tools in many laboratories, offering new operational possibilities, greater accuracy and more efficient management of workflows than ever before (4). Thanks to these and other CAD/CAM technologies, it is now possible to design and produce prosthetic, orthodontic, gnathological, surgical and implant devices (5–7).

However, the use of 3D technologies is not always feasible and practicable and must be evaluated based on the specific clinical application, the materials used and the choice between in-house production and outsourcing, particularly for metalworking (8,9).

The phases of the 3D workflow in a dental laboratory

In the dental laboratory, the use of 3D is divided into different phases of the workflow (10). The first is that of acquisition, which can be done via a digital impression taken directly in the office with intraoral scanners or via a traditional impression or a plaster model that is subsequently digitised using a benchtop scanner.

The generated STL file represents the starting point for modelling the device prescribed by the dentist. Using the CAD software, the digital design of the required product is created, working directly on the acquired STL file. This allows for the design of crowns, bridges, implant structures, surgical guides, bites and orthodontic appliances.

Once the project is completed, the process advances to the production phase, which can be carried out using subtractive CAM technologies – such as milling – or additive ones via 3D printing (11,12).

The advantage is twofold: on the one hand, the times and costs associated with manual phases, such as wax modelling, are reduced; on the other, a standard product is obtained in terms of mechanical-chemical characteristics, with a shape that is perfectly reproducible starting from the STL file of the project (3).

3D Dental Technology Laboratory: In-house or External production centres

For all these operational phases, particularly the CAM phases, the dental laboratory can choose whether to rely on external production centres (industrial manufacturing) or keep the production internal, in-house (13). This choice is particularly relevant in the management of metallic materials (9).

In fact, metals are more difficult to work with digital workflow inside the laboratory, as they require advanced and very expensive technologies such as selective laser melting (SLM or DMLS), as well as controlled environments for post-processing treatment (9,14). Even among subtractive technologies, metal milling presents certain challenges: it is a particularly abrasive process for the cutters, which deteriorate rapidly.

Pros and Cons of In-House Production

Today, “soft” metals (chromium-cobalt) are also available which are easier to mill with standard machinery, but which require subsequent sintering treatment. This involves a dimensional shrinkage of approximately 10%, which must be carefully considered in the design phase (15).

As a result, many laboratories prefer to entrust the production of metal structures to milling centres or specialised industrial services. These centres rely on high-precision machinery, which is often more expensive and complex to maintain for a medium-small company and offer high quality standards within competitive timeframes.

In-house production proves more advantageous for other types of processes, in particular for the printing of 3D models, resin devices (such as temporaries or bite splints) or customised surgical guides (16). Ceramics are also easy to work with in the laboratory. Zirconium, for example, is milled during the pre-sintering phase with a very soft, plaster-like consistency. After sintering, it also undergoes a dimensional contraction (of approximately 20%) and is then characterised by the technician (17,18).

Furthermore, with the spread of high-performance 3D printers and increasingly reliable and certified composite/ceramic hybrid materials, many laboratories are able to obtain clinically valid results even in the direct production of final restorations (19).

Using the 3D printed model

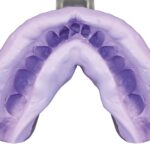

A crucial issue remains the use of the 3D printed model(20): when is it really necessary and when can it be avoided? The answer depends on the type of work and the materials used. Certainly 3D printed models are always useful as medico-legal documentation, verification and adaptation tools, as replicas for the patient or as aids for communication between the practice, laboratory, and patient.

In the orthodontic field, 3D models are the basis for the thermoforming of aligners and for the digital archiving of cases, while in implantology they represent a fundamental aid for the control of the fit of prostheses on implants for complex cases (21). They are also useful for testing the fit of surgical guides in preparation for guided surgery.

In natural-tooth prosthetics, models are especially useful when precise occlusal control and passive fitting are required. They serve as a reference for finishing, for checking contacts and for aesthetic control. 3D printed models can also be used to make masks that are useful for creating direct aesthetic mock-ups (22).

However, in some selected cases it is possible to work in completely model free mode, that is, without going through the printing of the model (23). This is the case, for example, with temporary restorations on teeth, preliminary restorations and permanent restorations on single or multiple implants. In these contexts, the adoption of model-free digital flows enables even faster management with even shorter job delivery times (24).

Advantages and limitations of 3D technologies

In conclusion, 3D technologies have profoundly changed the way the dental laboratory works, bringing significant advantages in terms of precision, speed and reproducibility.

However, to get the most out of these technologies, it is essential to have a good understanding of the intended uses, the limitations of the materials and to effectively balance in-house production with industrial outsourcing.

Only this way will the laboratory be able to offer high-quality prosthetic and orthodontic devices, effectively responding to the clinical needs of the present and the future.

References:

1. Carneiro Pereira AL, Bezerra de Medeiros AK, de Sousa Santos K, Oliveira de Almeida É, Seabra Barbosa GA, da Fonte Porto Carreiro A. Accuracy of CAD-CAM systems for removable partial denture framework fabrication: A systematic review. J Prosthet Dent. 2020 Mar 5;

2. Papadiochou S, Pissiotis AL. Marginal adaptation and CAD-CAM technology: A systematic review of restorative material and fabrication techniques. J Prosthet Dent. 2018 Apr;119(4):545–51.

3. Alghazzawi TF. Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res. 2016 Apr;60(2):72–84.

4. Alghauli MA, Aljohani W, Almutairi S, Aljohani R, Alqutaibi AY. Advancements in digital data acquisition and CAD technology in Dentistry: Innovation, clinical Impact, and promising integration of artificial intelligence. Clinical eHealth. 2025 Dec;8:32–52.

5. Grande F, Pavone L, Molinelli F, Mussano F, Srinivasan M, Catapano S. CAD-CAM complete digital dentures: An improved clinical and laboratory workflow. J Prosthet Dent. 2024 Dec 28;S0022-3913(24)00821-7.

6. Grande F, Ortensi L, Ortensi M, Catapano S. Prosthetic implant rehabilitation using the scan-analog protocol: a clinical case. Dental Cadmos. 2023 Oct;91(08):682.

7. Pozzi A, Tallarico M, Moy PK. Four-implant overdenture fully supported by a CAD-CAM titanium bar: A single-cohort prospective 1-year preliminary study. J Prosthet Dent. 2016 Oct;116(4):516–23.

8. Revilla-León M, Özcan M. Additive Manufacturing Technologies Used for Processing Polymers: Current Status and Potential Application in Prosthetic Dentistry. J Prosthodont. 2019 Feb;28(2):146–58.

9. Revilla-León M, Meyer MJ, Özcan M. Metal additive manufacturing technologies: literature review of current status and prosthodontic applications. Int J Comput Dent. 2019;22(1):55–67.

10. Masri R, Driscoll C. Odontoiatria digitale: Presupposti teorici e applicazioni cliniche. Edra; 2017. 610 p.

11. Dawood A, Marti Marti B, Sauret-Jackson V, Darwood A. 3D printing in dentistry. Br Dent J. 2015 Dec;219(11):521–9.

12. Christensen GJ. Impressions Are Changing: Deciding on Conventional, Digital or Digital Plus In-Office Milling. J Am Dent Assoc. 2009 Oct 1;140(10):1301–4.

13. Grenade C, Mainjot A, Vanheusden A. Fit of single tooth zirconia copings: comparison between various manufacturing processes. The Journal of Prosthetic Dentistry [Internet]. 2011 Apr 1 [cited 2025 May 1];105(4):249–55. Available from: https://www.sciencedirect.com/science/article/pii/S0022391311600401

14. Zhou Y, Dong X, Li N, Yan J. Effects of post-treatment on metal-ceramic bond properties of selective laser melted Co-Cr dental alloy. Part 1: Annealing temperature. J Prosthet Dent. 2023 Apr;129(4):657.e1-657.e9.

15. Taşın S, Turp I, Bozdağ E, Sünbüloğlu E, Üşümez A. Evaluation of strain distribution on an edentulous mandible generated by cobalt-chromium metal alloy fixed complete dentures fabricated with different techniques: An in vitro study. J Prosthet Dent. 2019 Jul;122(1):47–53.

16. Reich S, Berndt S, Kühne C, Herstell H. Accuracy of 3D-Printed Occlusal Devices of Different Volumes Using a Digital Light Processing Printer. Appl Science. 2022 Jan;12(3):1576.

17. Nakamura T, Nakano Y, Usami H, Okamura S, Wakabayashi K, Yatani H. In vitro investigation of fracture load and aging resistance of high-speed sintered monolithic tooth-borne zirconia crowns. J Prosthodont Res. 2020 Apr;64(2):182–7.

18. Ohkuma K, Kameda T, Terada K. Five-axis laser milling system that realizes more accurate zirconia CAD/CAM crowns by direct milling from fully sintered blocks. Dent Mater J. 2019 Feb 8;38(1):52–60.

19. Mangano FG, Cianci D, Pranno N, Lerner H, Zarone F, Admakin O. Trueness, precision, time-efficiency and cost analysis of chairside additive and subtractive versus lab-based workflows for manufacturing single crowns: An in vitro study. J Dent. 2024 Feb;141:104792.

20. Choi JW, Ahn JJ, Son K, Huh JB. Three-Dimensional Evaluation on Accuracy of Conventional and Milled Gypsum Models and 3D Printed Photopolymer Models. Materials. 2019 Jan;12(21):3499.

21. Jin G, Shin SH, Shim JS, Lee KW, Kim JE. Accuracy of 3D printed models and implant-analog positions according to the implant-analog–holder offset, inner structure, and printing layer thickness: an in-vitro study. J Dent. 2022 Oct 1;125:104268.

22. Garcia PP, da Costa RG, Calgaro M, Ritter AV, Correr GM, da Cunha LF, et al. Digital smile design and mock-up technique for esthetic treatment planning with porcelain laminate veneers. J Conserv Dent. 2018;21(4):455–8.

23. Piscopo M, Grande F, Catapano S. Full Digital Workflow for Prosthetic Full-Arch Immediate Loading Rehabilitation Using OT-Bridge System: A Case Report. Prosthesis. 2022 Jun;4(2):213–23.

24. Stanley M, Paz AG, Miguel I, Coachman C. Fully digital workflow, integrating dental scan, smile design and CAD-CAM: case report. BMC Oral Health. 2018 Aug 7;18(1):134.

Would you like more information about Zhermack Dental products and solutions?

Contact us

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.