In recent years, dentistry has undergone a radical transformation thanks to the introduction of digital technologies (1). They have become widespread in both dental practices, with the adoption of intraoral scanners (1), and dental laboratories, through the use of CAD (Computer Aided Design) (2) and CAM (Computer Aided Manufacturing) digital manufacturing systems, using both subtractive and additive technologies (3).

Digital workflow phases in dentistry

Nowadays, in the case of many types of restoration, it is possible to follow a completely digitalised workflow, known as “full-digital”, which allows prostheses to be created without the need for a physical model, starting directly from the intraoral scan (4).

Regardless of whether the workflow is partially or totally digital, there are still three fundamental phases for the creation of a prosthesis (2,5,6):

- Digital acquisition of clinical data using direct intraoral scanning or extraoral scanning of the impression material or of the plaster model obtained from the latter.

- Virtual design (CAD) or digital wax model of restorations, starting from the patient’s digital model.

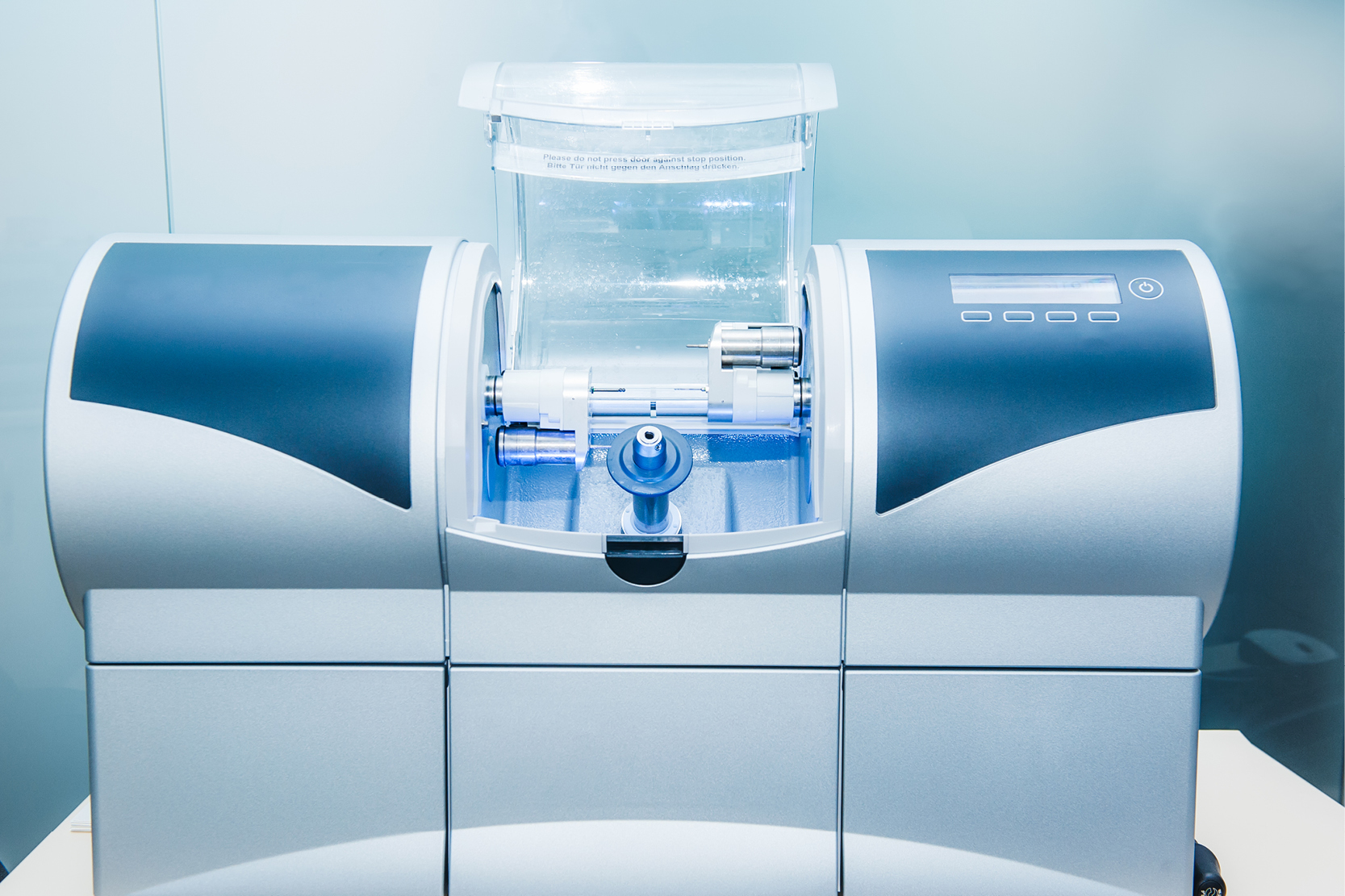

- Computer-aided manufacturing (CAM) of prosthetic devices, which is the creation of the restoration starting from the digital design developed in the CAD phase by means of milling or 3D printing (7).

It is important to note that each of these steps can be performed with different hardware and software. This is where the distinction between closed and open systems arises.

Closed and open systems in the dental digital workflow

A closed system is a “technological ecosystem” in which scanners (both intraoral and extraoral), CAD software and CAM machines are designed to work exclusively in combination with each other. If the workflow does not allow any way to exit the system to use external software or devices, it is described as a completely closed system.

If it is possible in some phases, however – for example between CAD and CAM or between data acquisition and CAD design – to interface with external software, then we can speak of a partially closed or semi-open system.

Conversely, an open system enables interoperability between devices and software from different manufacturers. An example might be an intraoral scanner that can send its data to another company’s CAD software, allowing the files to be exported to a laboratory with different CAM systems.

The ability of a device or software to communicate with different software depends on its ability to export working 3D files using standard formats (such as STL (Standard Tessellation Language) or PLY (Polygon File Format)). This step may be allowed but still lead to a different 3D reconstruction due to the different algorithms used by the software to structure the image (8,9).

Features and advantages of closed systems

Certainly, closed systems have guaranteed compatibility, in the sense that each component is designed to work with the others, reducing technical problems to a minimum (10). They offer simpler user interfaces, an easier learning curve and centralised technical support that is often more effective in resolving issues.

On the other hand, such systems severely limit integration with third-party devices and software, for example reducing the possibilities of producing restorations with different technologies. They also offer less design flexibility: clinicians and technicians are bound by the tools, digital libraries and components already integrated into the system, with more limited options for modifications and customisations (11).

Features and advantages of open systems

Open systems, on the other hand, offer greater flexibility and customisation, allowing you to select the workflow components that best suit your clinical and laboratory needs. These systems can be put together and implemented gradually, allowing the purchase of single compatible devices – often cheaper – that can be upgraded over time.

However, even with standard formats such as STL or PLY, errors can occur when importing or exporting files between different software (8,9). Furthermore, for example, with the STL format you may lose information such as the colour or surface texture of the original scan (5,12).

In the event of technical problems, it is often more difficult to identify the cause or what is responsible for the problem, since the workflow involves multiple software applications and hardware systems. This also leads to greater management complexity: in-depth knowledge of the individual software and protocols applied is required to ensure the efficient operation of the entire process.

How to choose a digital workflow in dentistry

Currently, the vast majority of digital systems in dentistry are open systems, which allow users to export files in STL format and import them into other software at any stage of the workflow.

However, the choice to work in an open or closed system depends on several factors, including the type of restoration to be produced, digital skills, the relationship with the dental laboratory or the possibility of working chairside, as well as the budget. For example, a small dental practice that wants to offer chairside solutions to patients might benefit from a closed system. Conversely, a practice already digitised or equipped with an internal laboratory might prefer an open system to take full advantage of the devices’ interoperability.

The type of rehabilitation also has an impact. In complex implant rehabilitations or in the full arch – where the integration of heterogeneous data is necessary, such as DICOM from CBCT, STL from intraoral and/or facial scans and XML from mandibular movements – open systems guarantee superior flexibility, improving the accuracy of the final result.

In conclusion, there is no single answer when it comes to choosing between an open and a closed system: it depends on clinical, financial and management variables. It is essential to be aware of the advantages and limitations of each option in order to adopt a digital strategy consistent with your professional needs and the quality of care offered to patients.

References:

1. Revilla-Leon M, Frazier K, da Costa JB, Kumar P, Duong ML, Khajotia S, et al. Intraoral scanners: An American Dental Association Clinical Evaluators Panel survey. J Am Dent Assoc. 2021 Aug 1;152(8):669-670.e2.

2. Alghazzawi TF. Advancements in CAD/CAM technology: Options for practical implementation. J Prosthodont Res. 2016 Apr;60(2):72–84.

3. Masri G, Mortada R, Ounsi H, Alharbi N, Boulos P, Salameh Z. Adaptation of Complete Denture Base Fabricated by Conventional, Milling, and 3-D Printing Techniques: An In Vitro Study. J Contemp Dent Pract. 2020 Apr 1;21(4):367–71.

4. Piscopo M, Grande F, Catapano S. Full Digital Workflow for Prosthetic Full-Arch Immediate Loading Rehabilitation Using OT-Bridge System: A Case Report. Prosthesis. 2022 Jun;4(2):213–23.

5. Masri R, Driscoll C. Odontoiatria digitale: Presupposti teorici e applicazioni cliniche. Edra; 2017. 610 p.

6. Grande F, Pavone L, Molinelli F, Mussano F, Srinivasan M, Catapano S. CAD-CAM complete digital dentures: An improved clinical and laboratory workflow. J Prosthet Dent. 2024 Dec 28;S0022-3913(24)00821-7.

7. Grande F, Tesini F, Pozzan MC, Zamperoli EM, Carossa M, Catapano S. Comparison of the Accuracy between Denture Bases Produced by Subtractive and Additive Manufacturing Methods: A Pilot Study. Prosthesis. 2022 Mar 28;4(2):151–9.

8. Erozan Ç, Ozan O. Evaluation of the Precision of Different Intraoral Scanner-Computer Aided Design (CAD) Software Combinations in Digital Dentistry. Med Sci Monit. 2020 Jan 3;26:e918529.

9. Song YL, Li J, Yin L, Huang T, Gao P. The feature-based posterior crown design in a dental CAD/CAM system. Int J Adv Manuf Technol. 2007 Jan 29;31(11–12):1058–65.

10. Grünheid T, McCarthy SD, Larson BE. Clinical use of a direct chairside oral scanner: an assessment of accuracy, time, and patient acceptance. Am J Orthod Dentofacial Orthop. 2014 Nov;146(5):673–82.

11. Tapie L, Lebon N, Mawussi B, Fron-Chabouis H, Duret F, Attal JP. Understanding dental CAD/CAM for restorations–accuracy from a mechanical engineering viewpoint. Int J Comput Dent. 2015;18(4):343–67.

12. Haddadi Y, Bahrami G, Isidor F. Effect of Software Version on the Accuracy of an Intraoral Scanning Device. Int J Prosthodont. 2018 Aug;31(4):375–6.

Would you like more information about Zhermack Dental products and solutions?

Contact us

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.