Addition silicones are the most precise materials used for the duplication of models in the dental laboratory. They are used for casting in the same way as gels (reversible hydrocolloids), but differ in that their hardening is non-reversible, therefore they cannot therefore be re-used.

Due to their precision, they are used mainly for applications requiring a particularly detailed copy, such as in the creation of auro galvan crowns (produced using electrodeposited gold and therefore extremely thin) or Maryland-type bridges, and are just one of many new metal-free products offering new treatment options to clinicians. The addition silicones used for duplication purposes are different to those commonly used as impression materials, being available in masses for mixing at a ratio of 1:1.

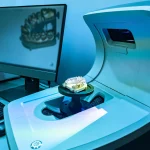

With regards to duplication work, the clinician is no longer limited to the reproduction of master models in plaster; indeed the range of resinous materials available is suited to a much wider range of applications, including model creation and duplication. The availability of high-precision resins allows the creation of sawcut models, for use in the applications described previously, or models for implant prosthetics or orthodontics.

These products are very similar to plaster, also in terms of their appearance, allowing them to be used in both analogue and the new digital systems.

The use of acrylic-type resins therefore allows the dentist to broaden his or her sphere of work, bringing certain tasks out of the traditional laboratory environment and in to the dental chair.

The MDP technique for the duplication of complete dentures is of particular interest, using a self-centring and self-aligning flask.

The prosthesis is placed with the toothed surface downwards in the lower part of the flask containing the impression material, usually a normal alginate, which is allowed to harden. The process is then repeated with the counter mould, which aligns itself precisely with the base.

The procedure takes no more than 30 minutes, after which the prosthesis can be returned to the patient, while the flask is sent to the laboratory to create the duplicate. This has clear advantages, both in terms of lessening patient discomfort and reduced operating times, and shows particular promise at a time when guided implant surgery is becoming more widespread. This approach allows a remodelling of the occlusal parameters, and can be used to create implant templates in transparent resin, again using a total prosthesis as a starting model.

Do you want more information on Zhermack Dental products and solutions?

Contact us

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.