10

Mar

Analogue and digital techniques in dentistry. Digital acquisition techniques and differences between analogue and digital impressions

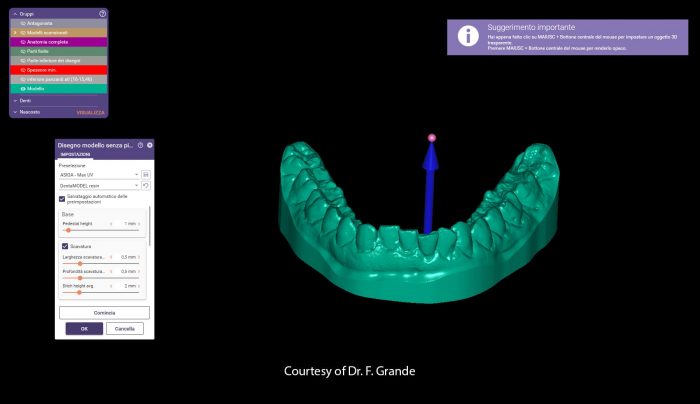

Digital impressions and the subsequent CAD (Computer Aided Design) and CAM (Computer Aided Manufacturing) workflows have become a common alternative to conventional techniques in the production of dental prostheses.

From a clinical point of view, the precision of finished prostheses is equally essential with both types of workflow. Accuracy depends on the individual stages of the workflow chosen. In the conventional analogue technique, for example, the impression, the master model, the shape and thickness of the die spacer applied to the stone abutment, the method adopted for producing the restoration and the investment material used for the lost wax casting all represent stages at which errors can accumulate [1,2].

The accuracy of digital systems, on the other hand, depends on the optical technology used, the possible need for contrast powders, the algorithm applied by the intraoral scanner, and the precision of the CAD-CAM prosthesis production technologies [3].

In recent years, thanks to advances in all these systems, procedures have been developed to simply and reduce the number of steps needed, and to make them more repeatable and less subject to operator error [4].

Nevertheless, totally digital workflow procedures do not always ensure adequate precision, and are also influenced by differences between one clinical case and another [5]. We can say that CAD-CAM systems involve 3 different and subsequent work phases [4]:

- acquisition of data from the oral environment

- a CAD process for designing the restorative prosthesis

- a CAM process for producing the restorative prosthesis

Workflows compared

The literature accurately describes the pros and cons of these phases [6]. While CAD and CAM systems offer real advantages, especially for the dental technician in terms of finished product quality and production times [7,8], the same cannot be said for the data acquisition process [3].

Analogue and digital workflows for the production of fixed zirconia prostheses on natural abutments were compared in a randomly selected dental practice and it was seen that conventional complete arch impressions take less time to produce than their digital counterparts [3].

Similar results were observed in another study on model production in dental practices, which showed that conventional impressions of complete arches took far less time to produce (7.6 minutes) than digital scans (20.4 minutes) [9].

Other studies, however, have produced contrasting results, indicating that analogue impressions can take longer than digital ones [10,11]. The type of scanner used, whether scanning powders are applied prior to taking the impression or not, the skill of the operator and even the scanning strategy (whether the digital scan covers the whole arch or just a hemiarch) are all factors that can influence results [3].

Workflow limitations and possibilities

In light of the literature, it is clear that impression taking time is far more operator dependent in digital procedures than in analogue ones. The same applies to the precision of results.

The fact that the accuracy of a digital impression depends on factors such as scanning strategy [12], lighting conditions [13], patient movements, mouth aperture [14], etc., makes results far more subject to variation than with conventional impressions.

In certain situations, as in the case of completely edentulous patients and impressions of multiple implants, scanners encounter difficulties caused by a lack of reference points and this can lead to errors due to the software’s mathematical interpretation of edentulous spaces [5,15,16].

In these and other situations, a mixed analogue and digital workflow could prove more effective, with an analogue impression being taken and scanned immediately, or a stone model cast and this being scanned with a desktop or laboratory scanner.

This would allow an originally analogue workflow to be converted into a digital workflow prior to production of the prosthesis, conserving all the benefits of analogue impression taking plus those of digital production in the dental laboratory [4].

Should I scan the impression or the model?

A number of factors need to be considered in order to decide whether to scan the analogue impression or the stone model. Extraoral scanners, also referred to as desktop or laboratory scanners, introduce a certain “visual distortion” when they perform a scan due to a lack of precision in the technology involved.

Scanning a stone model introduces further inaccuracies due to the impression material (which always has an elastic recovery < al 100% and preserves a certain amount of distortion when removed from the oral cavity) and due to the stone model itself, which expands slightly when it sets [4].

On the surface, a workflow based on impression scanning would therefore seem preferable. However, it must be remembered that not all impression materials are scannable [17] and that the application of scanning powders adds to thickness and can therefore generate errors [18].

In addition, scanning a negative anatomy is not always advantageous since the light of the scanner may not penetrate to certain areas of the impression (especially the undercuts), or may be reflected incorrectly, resulting in the incomplete acquisition of the real anatomy [19].

The decision whether to scan the impression of the model should therefore be based on the clinical conditions. In the case of teeth prepared for fixed prostheses, it may prove more convenient to scan the stone model in order to allow the extraoral scanner to record accurately all the surfaces and margins of the abutments.

In the case of implant prostheses, on the other hand, when the accurate registration of implant position is of fundamental importance, impression scanning from scannable analogues may prove the best solution as it minimises the risk of errors due to the movement of analogues on transfers caused by expansion of the stone.

To conclude, as can be seen from the scientific literature, we can say that fully and partly digital workflows are both practical options in dentistry and can facilitate and improve various clinical and dental procedures.

To obtain predictable and reliable results, however, the best workflow must be selected on the basis of the clinical case and the dentist’s experience of the systems and flows involved. It is important to recognise the limitations of digital technology and the knowledge and skills acquired from analogue procedures remain valid.

Without this awareness, the risk of errors, even of an unknown nature, is higher with digital processes than with a fully analogue workflow.

Zhermack has developed a range of scannable impression materials for dentists in search of high performance solutions.

Hydrorise Implant is Zhermack’s range of scannable, high rigidity addition silicones for implant prostheses. These materials can easily be scanned using structured light extraoral scanners even without the application of scanning powders or sprays.

In the field of hydrocolloids, Zhermack has developed Hydrogum 5, a scannable alginate, while in the field of bite registration silicones, Occlufast CAD is the latest digital evolution of our acclaimed Occlufast Rock.

Bibliography:

[1] Abduo J, Lyons K, Swain M. Fit of zirconia fixed partial denture: a systematic review. J Oral Rehabil 2010;37:866–76. https://doi.org/10.1111/j.1365-2842.2010.02113.x.

[2] Schönberger J, Erdelt K-J, Bäumer D, Beuer F. Marginal and internal fit of posterior three-unit fixed zirconia dental prostheses fabricated with two different CAD/CAM systems and materials. Clin Oral Investig 2017;21:2629–35. https://doi.org/10.1007/s00784-017-2064-8.

[3] Sailer I, Mühlemann S, Fehmer V, Hämmerle CHF, Benic GI. Randomized controlled clinical trial of digital and conventional workflows for the fabrication of zirconia-ceramic fixed partial dentures. Part I: Time efficiency of complete-arch digital scans versus conventional impressions. J Prosthet Dent 2019;121:69–75. https://doi.org/10.1016/j.prosdent.2018.04.021.

[4] Gherlone E. L’impronta in protesi dentaria. Masson, 2005. n.d.

[5] Patzelt SBM, Vonau S, Stampf S, Att W. Assessing the feasibility and accuracy of digitizing edentulous jaws. J Am Dent Assoc 2013;144:914–20. https://doi.org/10.14219/jada.archive.2013.0209.

[6] Davidowitz G, Kotick PG. The use of CAD/CAM in dentistry. Dent Clin North Am 2011;55:559–70, ix. https://doi.org/10.1016/j.cden.2011.02.011.

[7] Benic GI, Sailer I, Zeltner M, Gütermann JN, Özcan M, Mühlemann S. Randomized controlled clinical trial of digital and conventional workflows for the fabrication of zirconia-ceramic fixed partial dentures. Part III: Marginal and internal fit. J Prosthet Dent 2019;121:426–31. https://doi.org/10.1016/j.prosdent.2018.05.014.

[8] Mühlemann S, Benic GI, Fehmer V, Hämmerle CHF, Sailer I. Randomized controlled clinical trial of digital and conventional workflows for the fabrication of zirconia-ceramic posterior fixed partial dentures. Part II: Time efficiency of CAD-CAM versus conventional laboratory procedures. J Prosthet Dent 2019;121:252–7. https://doi.org/10.1016/j.prosdent.2018.04.020.

[9] Grünheid T, McCarthy SD, Larson BE. Clinical use of a direct chairside oral scanner: an assessment of accuracy, time, and patient acceptance. Am J Orthod Dentofacial Orthop 2014;146:673–82. https://doi.org/10.1016/j.ajodo.2014.07.023.

[10] Yuzbasioglu E, Kurt H, Turunc R, Bilir H. Comparison of digital and conventional impression techniques: evaluation of patients’ perception, treatment comfort, effectiveness and clinical outcomes. BMC Oral Health 2014;14:10. https://doi.org/10.1186/1472-6831-14-10.

[11] Joda T, Brägger U. Time-Efficiency Analysis Comparing Digital and Conventional Workflows for Implant Crowns: A Prospective Clinical Crossover Trial. Int J Oral Maxillofac Implants 2015;30:1047–53. https://doi.org/10.11607/jomi.3963.

[12] Latham J, Ludlow M, Mennito A, Kelly A, Evans Z, Renne W. Effect of scan pattern on complete-arch scans with 4 digital scanners. J Prosthet Dent 2020;123:85–95. https://doi.org/10.1016/j.prosdent.2019.02.008.

[13] Revilla-León M, Jiang P, Sadeghpour M, Piedra-Cascón W, Zandinejad A, Özcan M, et al. Intraoral digital scans-Part 1: Influence of ambient scanning light conditions on the accuracy (trueness and precision) of different intraoral scanners. J Prosthet Dent 2020;124:372–8. https://doi.org/10.1016/j.prosdent.2019.06.003.

[14] Ender A, Attin T, Mehl A. In vivo precision of conventional and digital methods of obtaining complete-arch dental impressions. J Prosthet Dent 2016;115:313–20. https://doi.org/10.1016/j.prosdent.2015.09.011.

[15] Patzelt SBM, Emmanouilidi A, Stampf S, Strub JR, Att W. Accuracy of full-arch scans using intraoral scanners. Clin Oral Investig 2014;18:1687–94. https://doi.org/10.1007/s00784-013-1132-y.

[16] Mizumoto RM, Yilmaz B, McGlumphy EA, Seidt J, Johnston WM. Accuracy of different digital scanning techniques and scan bodies for complete-arch implant-supported prostheses. J Prosthet Dent 2020;123:96–104. https://doi.org/10.1016/j.prosdent.2019.01.003.

[17] García-Martínez I, CáceresMonllor D, Solaberrieta E, Ferreiroa A, Pradíes G. Accuracy of digitization obtained from scannable and nonscannable elastomeric impression materials. The Journal of Prosthetic Dentistry 2021;125:300–6. https://doi.org/10.1016/j.prosdent.2020.01.002.

[18] Runkel C, Güth J-F, Erdelt K, Keul C. Digital impressions in dentistry—accuracy of impression digitalisation by desktop scanners. Clin Oral Invest 2020;24:1249–57. https://doi.org/10.1007/s00784-019-02995-w.

[19] Bosniac P, Rehmann P, Wöstmann B. Comparison of an indirect impression scanning system and two direct intraoral scanning systems in vivo. Clin Oral Invest 2019;23:2421–7. https://doi.org/10.1007/s00784-018-2679-4.

Do you want more information on Zhermack Dental products and solutions?

Contact us!

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.

Zhermack SpA has been one of the most important producers and international distributors of alginates, gypsums and silicone compounds for the dental sector for over 40 years. It has also developed solutions for the industrial and wellbeing sectors.

Zhermack SpA - Via Bovazecchino, 100 - 45021 Badia Polesine (RO), Italy.